Product Details

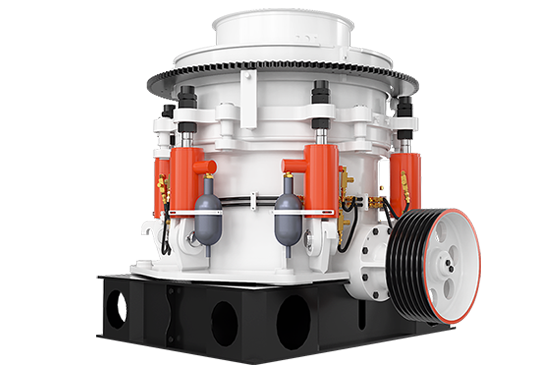

HP serie multiple cylinder cone crusher is the latest model designed by our company, mainly used for hard materials crushing. This series machine has much better performance than the spring cone crusher, and it has bigger capacity and better final products shape.

Features

spindle support, so it’s able to withstand greater crushing force and greater stroke. If added with special crushing cavity adapting lamination principle, the machine has higher efficiency.

Large production capacity: The machine has a perfect design combination of crushing stroke, crushing speed and crushing cavity shape, which makes the machine have 35%~60% higher output than the old spring cone Crusher in case of same fixed cone diameter.

High quality of finished products: The multi-cylinder hydraulic cone crusher uses special crushing cavity, as well as the principle of laminated design, so that the cube proportions of finished product is significantly increased, with less needle-shaped stones and more evenly particle levels.

Benefits Features

1. Full hydraulic protection and adjustment device, which is labor and time savings.

2. Application of materials-beds pressure crushing way, high utilization rate, flawless particle, uniform size.

3. Newest PLC automatic controlling system; provide reliable and safe protection.

4. Equipped with remote touch-screen operation interface and Display live working status.

Principles

The rotating of motor drives pulley or coupling, motor shaft and cone axis to drive eccentric shaft to do periodic rotation-swing movement. After materials entering into the crushing cavity, they will be crushed by mutual impact extrusion, grinding and rubbing of the eccentric shaft and mortar roll, so as to achieve desired crushing effect. Hydraulic overload system can enlarge discharge hole to discharge obstruction when the machine is jammed, so it plays a positive role as insurance and significantly reduces maintenance and increases productivity.

| Model | Cavity Type | Feeding Size(mm) | Closed side feeding size(mm) | Minimum Discharge Opening (mm) | Motor Power(kw) | Capacity(t/h) | Weight (t) |

| HP100 | C1 Extra coarse | 175 | 140 | 19 | 4P 100 | 45-140 | 8.4 |

| C2 Coarse | 125 | 105 | 13 | ||||

| M Medium | 100 | 70 | 10 | ||||

| F1 Fine | 71 | 50 | 9 | ||||

| F2 Extra fine | 33 | 20 | 6 | ||||

| HP200 | C2 Coarse | 235 | 190 | 19 | 4P 160 | 90-250 | 10.4 |

| M Medium | 171 | 120 | 16 | ||||

| F1 Fine | 150 | 95 | 13 | ||||

| F2 Extra fine | 116 | 70 | 8 | ||||

| HP300 | C1 Extra coarse | 265 | 230 | 25 | 4P 220 | 115-440 | 18.1 |

| C2 Coarse | 240 | 210 | 20 | ||||

| M Medium | 190 | 150 | 15 | ||||

| F1 Fine | 145 | 105 | 11 | ||||

| F2 Extra fine | 120 | 80 | 8 | ||||

| HP400 | C1 Extra coarse | 360 | 290 | 30 | 4P 315 | 140-630 | 25 |

| C2 Coarse | 310 | 250 | 25 | ||||

| M Medium | 260 | 196 | 20 | ||||

| F1 Fine | 182 | 110 | 13 | ||||

| F2 Extra fine | 135 | 90 | 10 | ||||

| HP500 | C1 Extra coarse | 370 | 330 | 38 | 4P 400 | 175-790 | 36 |

| C2 Coarse | 320 | 290 | 28 | ||||

| M Medium | 245 | 210 | 22 | ||||

| F1 Fine | 180 | 130 | 13 | ||||

| F2 Extra fine | 150 | 95 | 10 | ||||

| HP800 | C1 Extra coarse | 450 | 352 | 38 | 4P 830 | 260-1200 | 68.5 |

| C2 Coarse | 373 | 298 | 32 | ||||

| M Medium | 340 | 275 | 25 | ||||

| F1 Fine | 280 | 230 | 16 | ||||

| F2 Extra fine | 235 | 150 | 10 |

Hign-tech Development Zone, Zhengzhou City, Henan, China

Hign-tech Development Zone, Zhengzhou City, Henan, China +86 18737120960

+86 18737120960 kevin@centbro.com

kevin@centbro.com

+86 18737120960

+86 18737120960

Hign-tech Development Zone, Zhengzhou City, Henan, China

Hign-tech Development Zone, Zhengzhou City, Henan, China