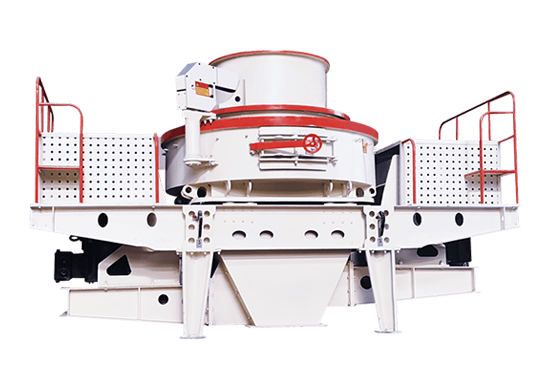

Product Details

The Hot-sale Types of Sand Making Machine

It is the key equipment for artificial sand making to provide high quality sand aggregate for building, highway, construction, concrete batching plant, etc.

The hot sale sand making machine includes artificial sand making machine, silica sand making machine, plaster sand making machine.

We also provide complete sand making production line, which includes sand making machine, sand washing machine, sand screen machine, vibrating feeder, belt conveyor,etc.

VSI crusher can process the following materials such as iron ore, copper ore, gold and silver ore, zinc, manganese, limestone, granite, basalt, cobble, coal, quartz and so on, which is widely used in the fields including rocks, abrasive, refractory, cement clinker, quartz, iron ore and concrete aggregate, building materials and so on.

Benefits Features

1.Oil supplied by two oil pumps, stops automatically if there is no oil; cooled by water, heating the motor firstly if start the machine in winter.

2.Hydraulic lifting when changing or checking the spare parts which makes it easy and convenient in maintenance.

3.Famous brand SKF or TIMKEN of the bearing makes the machine work well and few problems.

4.Vibrating alarm device; if the crusher works abnormally, alarm will sound to make the machine stop working so as to protect the crusher.

5.Special feeding structure; rock on rock, and rock on iron in the crusher making the stone to be crushed and reshaped.

6.Unique dustproof seal system, protects the lubrications parts from the dust outside.

7.Perfect design on material bumping angle reduces the friction between raw material and quick-wear parts, prolongs the service time of quick-wear parts and cuts the cost.

| Model | VSI7611 | VSI8518 | VSI9526 | VSI1140 | ||

| Capacity (t/h) | Center and Ring Feeding | 120~180 | 200~260 | 300~380 | 450~520 | |

| Center Feeding | 60~90 | 100~130 | 150~190 | 225~260 | ||

| Max Feed Size (mm) | Soft material | <35 | <40 | <45 | <50 | |

| Hard material | <30 | <35 | <40 | <45 | ||

| Rotation speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | ||

| Power for double motor (Kw) | 110-150 | 180-220 | 264-320 | 400-440 | ||

| Overall Dimension L×W×H (mm) | 4100×2250×2285 | 4140×2280×2425 | 4560×2450×2780 | 5100×2690×3200 | ||

| Weight (t) | 7.8 | 10.3 | 16 | 25.6 | ||

| Power Source | AC380V ,50Hz | |||||

| Vibrating Sensor | Inspect scope: 0.1-20mm/s adjusted continuously | |||||

| Lubrication hydraulic pressure station | flow quantity(L/min) | 6 | ||||

| Power for double oil pump | 2×0.31 | |||||

| Safety | To make sure the supply of the oil with double oil pump; stop working without oil or hydraulic pressure; temperature falls when the water cool; start the motor by heating it in winter. | |||||

| Overall Dimension L×W×H (mm) | 820×520×1270 | |||||

| Power for oil box heater | 2 | |||||

Hign-tech Development Zone, Zhengzhou City, Henan, China

Hign-tech Development Zone, Zhengzhou City, Henan, China +86 18737120960

+86 18737120960 kevin@centbro.com

kevin@centbro.com

+86 18737120960

+86 18737120960

Hign-tech Development Zone, Zhengzhou City, Henan, China

Hign-tech Development Zone, Zhengzhou City, Henan, China