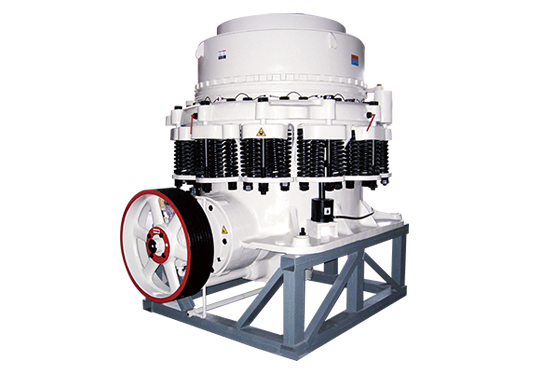

Product Details

Spring Cone crusher is used for crushing of ores and rocks, the advantages are: reliable structure, high efficiency, easy to adjust and economical. The safety spring system is the overload protection device, which makes foreign materials go through the machine without bring any hurt to it. The sealing models are oil and water, which segregate the stone powder and lubricating system. The crushing chamber is decided by the purpose of ore, the standard model is suitable for medium crushing, the medium model is suitable for fine crushing and the short head model is suitable for fine crushing.

Benefits Features

1. High performance and lower cost.

Optimized chamber-type, combined speed with stroke reasonably, stable and reliable performance, high production capacity, low production cost, and final cubic products can be increased with uniform size and reasonable grade.

2. Operate safety and reliability

With large-diameter spindle and heavy main frame, the equipment are strong, durable, and operate reliability. The independent multi-point control oil lubricating system ensures the double protection of the bearing lubrication. The automatic safety protection can be achieved by over-iron protection device and the automatic control system.

3. Easy to operate and maintain

All the parts can be disassembled from top or sides, so that the stable and movable cones assembly can be disassembled easily. The crushing chamber can be cleaned by the hydraulic clearing chamber quickly, so it can greatly reduce the down time.

| Model | Diameter of crushing cone(mm) | Feeding size(mm) | Adjusting Range of Discharge Opening(mm) | Capacity(t/h) | Power(KW) | Eccentric Shaft Rotate Speed(r/min) | Weight(t) | Overall Dimension(mm) |

| PYB600 | Φ600 | ≤ 75 | 12-25 | 15-25 | 30 | 356 | 5 | 2234 x 1370 x 1675 |

| PYD600 | Φ600 | ≤ 35 | 3-13 | 5-23 | 30 | 356 | 5.3 | 2234 x 1370 x1675 |

| PYB900 | Φ900 | ≤ 115 | 15-50 | 50-90 | 55 | 333 | 11.2 | 2692 x1640 x2350 |

| PYZ900 | Φ900 | ≤ 60 | 5-20 | 20-65 | 55 | 333 | 11.2 | 2692 x 1640 x 2350 |

| PYD900 | Φ900 | ≤ 50 | 3-13 | 15-50 | 55 | 333 | 11.3 | 2692 x 1640 x 2350 |

| PYB1200 | Φ1200 | ≤ 145 | 20-50 | 110-168 | 110 | 300 | 24.7 | 2790 x 1878 x 2844 |

| PYZ1200 | Φ1200 | ≤ 100 | 8-25 | 42-135 | 110 | 300 | 25 | 2970 x 1878 x 2844 |

| PYD1200 | Φ1200 | ≤ 50 | 3-15 | 18-105 | 110 | 300 | 25.3 | 2790 x 1878 x 2844 |

| PYB1750 | Φ1750 | ≤ 215 | 25-50 | 280-480 | 160 | 245 | 50.3 | 3910 x 2894 x 3809 |

| PYZ1750 | Φ1750 | ≤ 185 | 10-30 | 115-320 | 160 | 245 | 50.3 | 3910 x 2894 x 3809 |

| PYD1750 | Φ1750 | ≤ 85 | 5-13 | 75-230 | 160 | 245 | 50.2 | 3910 x 2894 x 3809 |

| PYB2200 | Φ2200 | ≤ 300 | 30-60 | 490-750 | 260-280 | 220 | 80 | 4622 x 3302 x 4470 |

| PYZ2200 | Φ2200 | ≤ 230 | 10-30 | 200-580 | 260-280 | 220 | 80 | 4622 x 3302 x4470 |

| PYD2200 | Φ2200 | ≤ 100 | 5-15 | 120-340 | 260-280 | 220 | 81.4 | 4622 x 3302 x4470 |

Hign-tech Development Zone, Zhengzhou City, Henan, China

Hign-tech Development Zone, Zhengzhou City, Henan, China +86 18737120960

+86 18737120960 kevin@centbro.com

kevin@centbro.com

+86 18737120960

+86 18737120960

Hign-tech Development Zone, Zhengzhou City, Henan, China

Hign-tech Development Zone, Zhengzhou City, Henan, China